Stainless Steel Buttweld Fittings Manufacturers & Suppliers in India

At Amardeep Steel Centre, we manufacture and supply all varieties of stainless steel butt weld fittings that are designed with high strength, durability as well as long life. Being reputable as a manufacturer, supplier, and exporter, we provide products of international standards with competitive price alternatives. Our fittings are designed to deliver leakproof and corrosion resistance performance to many industries where reliability and safety are paramount. Our products are relied upon to provide quality products in various applications despite their high-level requirements, whether it is power generation and oil and gas or chemical processing and marine engineering.

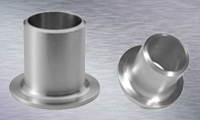

We offer a wide selection of SS Buttweld Fittings, including elbows, tees, reducers, stub ends, caps, and crosses, available in both seamless and welded forms. Our range of Stainless Steel Buttweld Pipe Fittings covers everything from high-pressure pipelines to low-maintenance utility systems. Whether you need a SS Buttweld fitting Elbow for directional changes, a Stainless Steel Seamless Pipe Fitting for strength-critical operations, or a welded buttweld fitting for cost-effective projects, our portfolio ensures every requirement is covered.

All the products are manufactured according to the international standards such as ASTM A403 and ASME SA403 and in sizes of 1/2 inch NB to 48 inch NB and schedules of Sch 5S to XXS. Our SS Seamless Buttweld Pipe Fittings have been characterized by high strength, whereas our SS Welded Buttweld Pipe Fittings have been characterized by versatility and affordability. Amardeep Steel is able to offer fittings that are a performance and peace of mind product with rigorous testing and total traceability.

Stainless Steel Butt Weld Pipe Fittings, Stainless Steel Pipe End Cap, SS Pipe Fittings Stockist, Supplier of ASTM A403 WP Stainless Steel 90 Degree Elbow in India, Stainless Steel Short Radius Elbow Supplier, ss buttweld fittings, Stainless Steel 180 Deg Bend, Buttweld Fittings Suppliers, Stainless Steel Seamless Pipe Fittings, Stainless Steel Pipe Bend Supplier in Mumbai, India.

Types Of Stainless Steel Buttweld Fittings

Stainless Steel Buttweld Fittings Specifications

Our SS Buttweld Fittings are manufactured to meet global piping standards with precise dimensions, wide size availability, and multiple grades. The specifications below highlight the sizes, schedules, and standards we offer to suit diverse industrial applications.

| Feature | Details |

|---|---|

| Standards | ASTM A403 / ASME SA403, ASME B16.9 / B16.28 |

| Size Range | ½” NB – 48” NB |

| Schedules | Sch 5 / 5S, 10 / 10S, 20, 40 / 40S, STD, XS, 60, 80 / 80S, 100, 120, 140, 160, XXS |

| Grades | WP 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 310, 347, 904L |

| End Types | Bevelled, Plain End, Threaded (NPT/BSPT/BSPP) |

| Forms | Elbow, Tee, Reducer, Stub-End, Cap, Cross, Bend |

Stainless Steel Buttweld Fittings – Material Equivalents

Below is a comparison of equivalent material grades for stainless steel buttweld fittings across various international standards:

| ASTM / ASME (USA) | UNS (Unified Numbering System) | EN / DIN / Werkstoff No. (Europe) | JIS (Japan) | BS (British Standard) |

|---|---|---|---|---|

| ASTM A403 WP304 | S30400 | 1.4301 / X5CrNi18-10 | SUS 304 | 304S31 |

| ASTM A403 WP304L | S30403 | 1.4306 / 1.4307 / X2CrNi18-9 | SUS 304L | 304S11 |

| ASTM A403 WP304H | S30409 | 1.4948 / X6CrNi18-11 | - | 304S51 |

| ASTM A403 WP316 | S31600 | 1.4401 / 1.4436 / X5CrNiMo17-12-2 | SUS 316 | 316S31 / 316S33 |

| ASTM A403 WP316L | S31603 | 1.4404 / 1.4435 / X2CrNiMo17-12-2 | SUS 316L | 316S11 / 316S13 |

| ASTM A403 WP316H | S31609 | - | - | - |

| ASTM A403 WP316Ti | S31635 | 1.4571 / X6CrNiMoTi17-12-2 | SUS 316Ti | 320S31 |

| ASTM A403 WP321 | S32100 | 1.4541 / X6CrNiTi18-10 | SUS 321 | 321S31 |

| ASTM A403 WP347 | S34700 | 1.4550 / X6CrNiNb18-10 | SUS 347 | 347S31 |

| ASTM A403 WP904L | N08904 | 1.4539 / X1NiCrMoCu25-20-5 | SUS 890L | - |

| ASTM A815 WP-S / WP-W (Duplex) | S31803 / S32205 | 1.4462 / X2CrNiMoN22-5-3 | SUS 329J3L | - |

| ASTM A815 WP-S / WP-W (Super Duplex) | S32750 | 1.4410 / X2CrNiMoN25-7-4 | - | - |

Chemical Composition of Stainless Steel Buttweld Fittings

The chemical makeup of stainless steel determines corrosion resistance, strength, and suitability for different environments. The table below shows the typical chemical composition for the most common grades of stainless steel buttweld fittings.

| Grade | C (max) | Cr | Ni | Mo | Other Elements |

|---|---|---|---|---|---|

| WP304 | 0.08 | 18.0-20.0 | 8.0-11.0 | - | Si: ≤1.0, Mn: ≤2.0 |

| WP304L | 0.035 | 18.0-20.0 | 8.0-13.0 | - | Si: ≤1.0, Mn: ≤2.0 |

| WP316 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | Si: ≤1.0, Mn: ≤2.0 |

| WP316L | 0.035 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | Si: ≤1.0, Mn: ≤2.0 |

| WP321 | 0.08 | 17.0-19.0 | 9.0-12.0 | - | Ti: ≥5xC, Si: ≤1.0, Mn: ≤2.0 |

Mechanical Properties of Stainless Steel Buttweld Fittings

Mechanical properties define how SS Buttweld Fittings perform under stress, pressure, and load. The table below provides typical minimum mechanical properties for common stainless steel buttweld fitting grades.

| Grade | Tensile Strength (min.) | Yield Strength (min.) | Elongation (min.) % | Hardness (max.) HRB | ||

|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | |||

| WP304 | 485 | 70 | 170 | 25 | 35 | 92 |

| WP304L | 485 | 70 | 170 | 25 | 35 | 92 |

| WP316 | 485 | 70 | 170 | 25 | 30 | 95 |

| WP316L | 485 | 70 | 170 | 25 | 30 | 95 |

| WP321 | 485 | 70 | 170 | 25 | 35 | 95 |

| WP347 | 485 | 70 | 170 | 25 | 35 | 95 |

Physical Properties of Stainless Steel Buttweld Fittings

Physical properties describe how Stainless Steel Seamless Pipe Fittings behave under different conditions of heat, weight, and external load.

| Property | Value |

|---|---|

| Density | 7.9 g/cm³ |

| Melting Point | 1400–1450 °C |

| Thermal Conductivity | 16.2 W/m-K (at 100 °C) |

| Electrical Resistivity | 0.072 ×10⁻⁶ Ω-m |

| Modulus of Elasticity | 193 GPa |

Dimensions for Common Pipe Schedules

The following table provides the Outside Diameter (OD) and corresponding wall thickness for common pipe schedules, which are critical for ensuring the fitting aligns perfectly with the pipe for a butt weld. The dimensions are standardized to ensure consistent fit and performance.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Schedule 10S Wall (mm) | Schedule 40S Wall (mm) | Schedule 80S Wall (mm) |

|---|---|---|---|---|

| 1/2" | 21.3 mm | 2.11 | 2.77 | 3.73 |

| 3/4" | 26.7 mm | 2.11 | 2.87 | 3.91 |

| 1" | 33.4 mm | 2.77 | 3.38 | 4.55 |

| 1 1/4" | 42.2 mm | 2.77 | 3.56 | 4.85 |

| 1 1/2" | 48.3 mm | 2.77 | 3.68 | 5.08 |

| 2" | 60.3 mm | 2.77 | 3.91 | 5.54 |

| 2 1/2" | 73.0 mm | 3.05 | 5.16 | 7.01 |

| 3" | 88.9 mm | 3.05 | 5.49 | 7.62 |

| 4" | 114.3 mm | 3.05 | 6.02 | 8.56 |

| 6" | 168.3 mm | 3.40 | 7.11 | 10.97 |

| 8" | 219.1 mm | 3.76 | 8.18 | 12.70 |

| 10" | 273.0 mm | 4.19 | 9.27 | 12.70 |

| 12" | 323.8 mm | 4.57 | 9.52 | 12.70 |

| 14" | 355.6 mm | 4.78 | 9.52 | 12.70 |

| 16" | 406.4 mm | 4.78 | 9.52 | 12.70 |

| 18" | 457.2 mm | 4.78 | 9.52 | 12.70 |

| 20" | 508.0 mm | 4.78 | 9.52 | 12.70 |

| 24" | 609.6 mm | 6.35 | 9.52 | 12.70 |

Stainless Steel Pipe Fittings Capacity

| Product | Standard Size Range* | Available Wall Thickness** | Seamless | Welded |

|---|---|---|---|---|

| Elbow | 1/2" – 24" | SCH 10S to XXS | ✔ | ✔ |

| 8" – 104" | SCH 5S to 80S / XS | ✔ | – | |

| Tee | 1/2" – 24" | SCH 10S to XXS | ✔ | ✔ |

| 8" – 104" | SCH 5S to 80S / XS | ✔ | – | |

| Reducer | 1/2" – 24" | SCH 10S to XXS | ✔ | ✔ |

| 8" – 104" | SCH 5S to 80S / XS | ✔ | – | |

| Cap | 1/2" – 80" | SCH 10S to SCH 160 | ✔ | – |

| Lap Joint Stub End | 1/2" – 24" | SCH 5S to 80S / XS | ✔ | ✔ |

| 8" – 80" | SCH 5S to 80S / XS | ✔ | – |

Standards of Stainless Steel Welded Fittings

|

|

Stainless Steel Buttweld Fittings Price List

| Product Description | Price Range (Per Piece) |

|---|---|

| Stainless Steel Schedule 10 Pipe Fittings | $12.10 – $6,050.00 |

| ASME/ANSI B16.9 Welding Fittings | $12.10 – $6,050.00 |

| SCH 80 Stainless Steel Butt Weld Fittings | $15 – $6,000 |

| SCH 5 Stainless Steel Buttweld Fittings | $19 – $5,000 |

| ASTM B366 WP 904L Stainless Steel Pipe Fittings (Mumbai) | $18 – $5,500 |

Applications of SS Buttweld Fittings

Stainless steel buttweld fittings are widely chosen for their strength, corrosion resistance, and ability to provide leak-proof joints in critical piping systems. Below are the key industries and applications where these fittings are extensively used.

- Oil & Gas Pipelines: SS buttweld fittings are used to connect and bend pipelines in upstream, midstream, and downstream operations. Their durability ensures long service life under high pressure and corrosive environments.

- Chemical & Petrochemical Plants: Resistant to acids, solvents, and chemicals, these fittings are ideal for transporting aggressive media. They help maintain process safety in refineries, fertilizer plants, and chemical processing units.

- Power Generation: In thermal and nuclear plants, SS fittings withstand high pressure and elevated temperatures. They are commonly used in steam lines, cooling water systems, and boiler feed piping.

- Food & Beverage Processing: With hygienic, non-reactive surfaces, stainless steel fittings are essential for sanitary piping. They ensure product purity in breweries, dairies, and packaged food production facilities.

- Marine & Offshore Structures: SS buttweld elbows, tees, and reducers are extensively used in shipbuilding and offshore rigs. Their excellent resistance to seawater corrosion makes them a preferred choice in marine environments.

- Water Treatment & Desalination: These fittings are critical for brine, freshwater, and wastewater piping systems. Their ability to resist pitting and chloride attack ensures reliable performance in desalination plants.

Related Products

- Stainless Steel 304 Butt weld Fittings

- Stainless Steel 304L Butt weld Fittings

- Stainless Steel 304H Butt weld Fittings

- Stainless Steel 310 Butt weld Fittings

- Stainless Steel 310S Butt weld Fittings

- Stainless Steel 316 Butt weld Fittings

- Stainless Steel 316L Butt weld Fittings

- Stainless Steel 316H Butt weld Fittings

- Stainless Steel 317 Butt weld Fittings

- Stainless Steel 317L Butt weld Fittings

- Stainless Steel 321 Butt weld Fittings

- Stainless Steel 321H Butt weld Fittings

- Stainless Steel 347 Butt weld Fittings

- Stainless Steel 347H Butt weld Fittings

- Stainless Steel 446 Butt weld Fittings

- Stainless Steel 904L Butt weld Fittings

Frequently Asked Questions About Stainless Steel Buttweld Fittings

Q1. What are Stainless Steel Buttweld Fittings?

Stainless Steel Buttweld Fittings are welded components used to join pipes, ensuring strong, leak-proof, and durable connections in industrial piping systems.

Q2. What grades are available in SS Buttweld Fittings?

They are commonly available in grades like 304, 304L, 316, 316L, 321, 347, and 904L.

Q3. What is the difference between seamless and welded buttweld fittings?

Seamless fittings, often referred to as Stainless Steel Seamless Pipe Fittings, are made from seamless pipes for higher strength, while welded fittings are cost-effective and ideal for moderate pressure use.

Q4. Can SS Buttweld Fittings resist corrosion?

Yes, stainless steel grades like 316L and 904L provide excellent resistance against corrosion, especially in chloride and acidic environments.

Q5. What standards govern SS Buttweld Fittings?

Standards include ASTM A403, ASME SA403, ASME B16.9, MSS SP-43, DIN, and EN.

Q6. What industries use SS Buttweld Fittings?

They are widely used in oil & gas, chemical, petrochemical, food processing, marine, and power generation sectors.

Q7. How are SS Buttweld Fittings tested for quality?

They undergo hydrostatic, radiography, PMI, hardness, and intergranular corrosion tests before dispatch.

Q8. What sizes are available?

Standard sizes range from ½” NB to 48” NB with schedules from Sch 5S to Sch XXS.